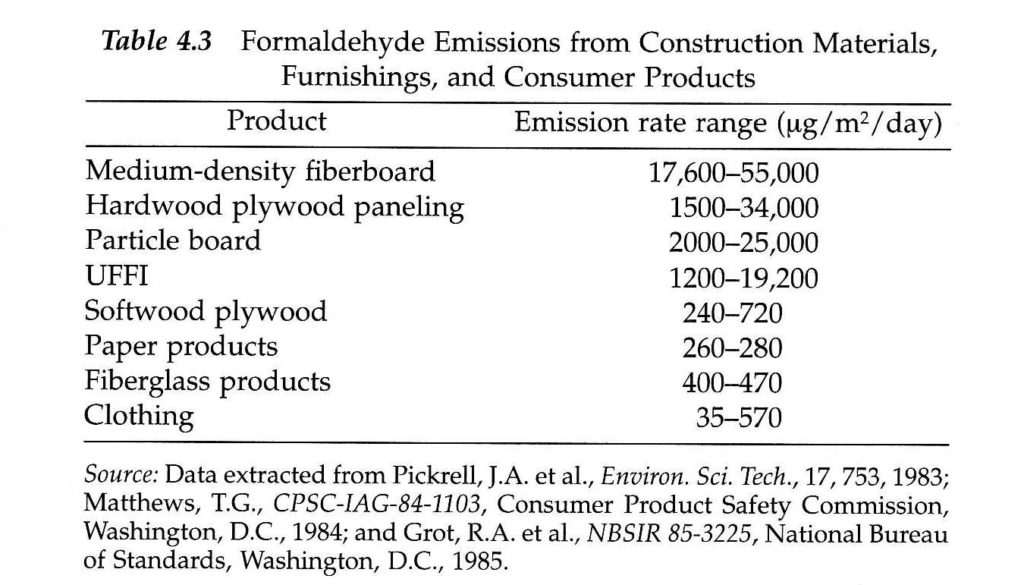

One of the first issues to address for pre-existing construction is proper selection of materials that have low VOCs and formaldehyde content (UF or Urea-Formaldehyde) and/or that outgas (release the noxious vapors) relatively quickly. Low emission products include:

- Low VOC paints

- Low VOC carpeting (though carpets tend to have inherent issues with collecting/releasing dust)

- Other mastic (waterproofing putty) products that have low levels of 4-phenylcyclohexane (4-PC) which produces a characteristic odor

- Pressed wood products that have low formaldehyde (HCHO) levels

- Formaldehyde-free varnishes and lacquers

- Softwood plywood

- Oriented-Strand board

- Decorative gypsum board

- Hardwood panels

- Pressed woods with PF (Phenol-Formaldehyde) resin release less HCHO than UF resins

You might want to AVOID:

- Medium-Density Fiberboard (MDF) sometimes used in cabinets, furniture and doors

- Hardwood plywood paneling

- Particleboard

- Pressed wood products with UF

- UF-based Acid Cured Finishes

- Homes insulated with UFFI (Urea-Formaldehyde Foam Insulation) though this is unlikely to be an issue

- High humidity (keep between 40 – 50 % RH)

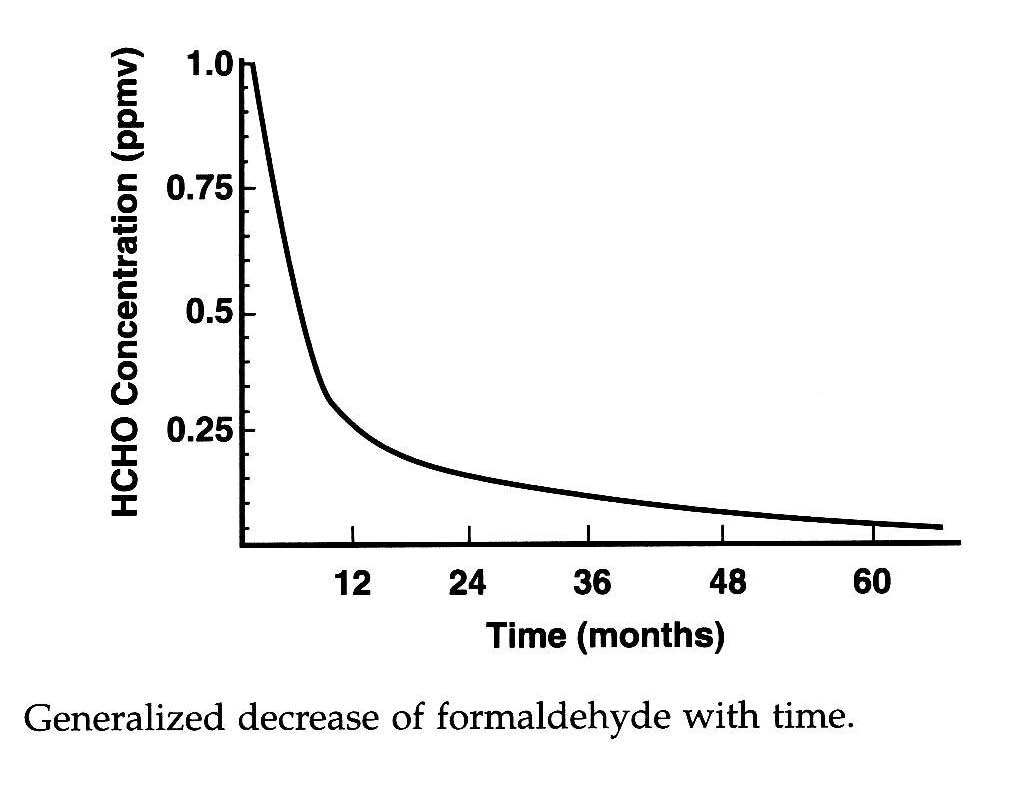

- Occupying the home or property until a proper out gassing period has passed – preferably during hotter weather

Then having an outgas period before occupation is good when possible. Preferably during hot, humid weather which tends to accelerate the exit of gaseous residues from the building materials. If you have an existing wood material that is emitting formaldehyde, then the can be treated with scavenging coatings or encapsulated with vinyl materials.

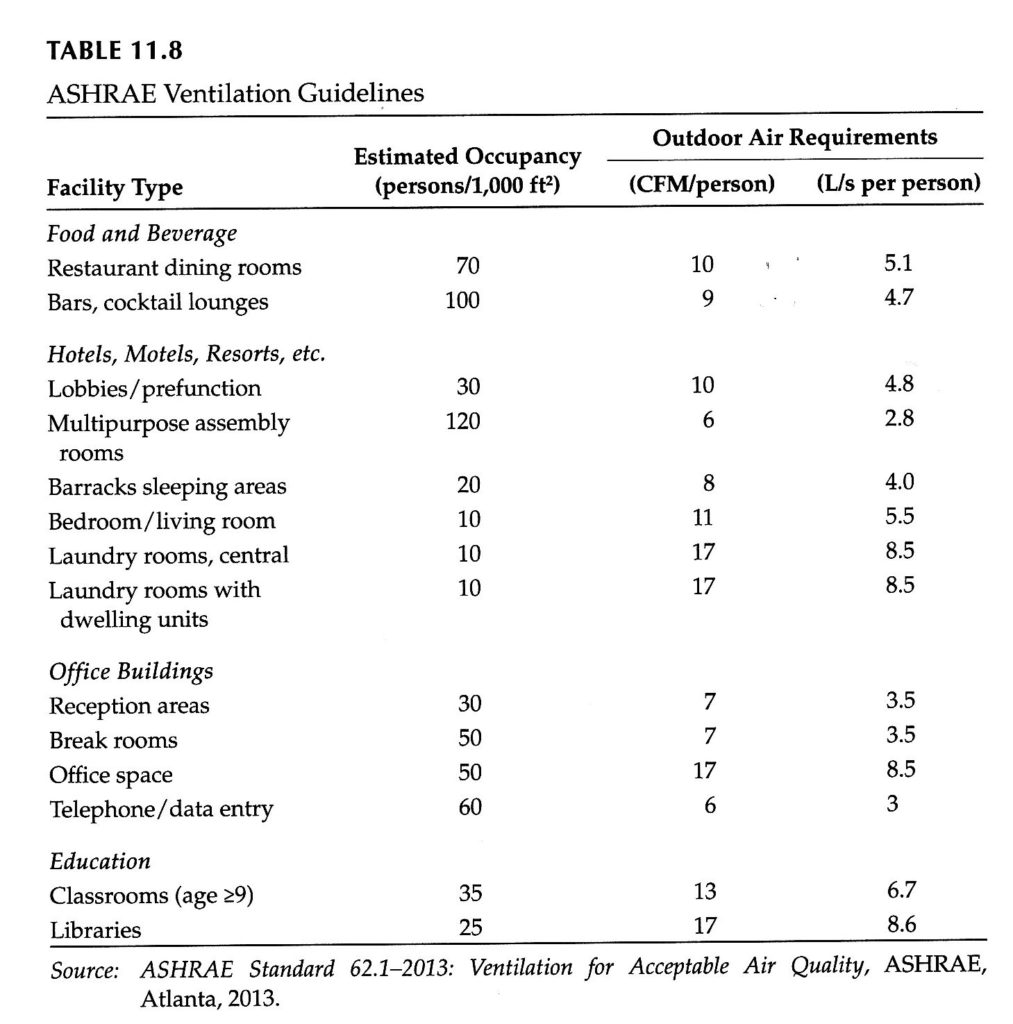

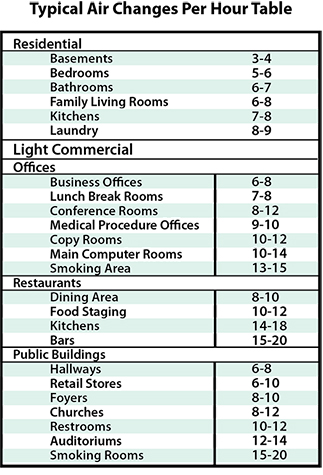

Another critical factor is having adequate ventilation, particularly during the initial outgas period. Many homes and multifamily dwellings are often built rather “tight” as a response to the desire for energy conservation and reducing moisture intrusion. If it is not a security issue, keeping the windows open even a crack on opposite sides to create a flowing cross-draft can assist out-gassing as well as opening chimney dampeners.

Factors in formaldehyde levels:

- Composition of building materials (formaldehyde potency in manufacture)

- Loading factor (amount of material in exposed surface area and volume)

- Material age

- Adequate ventilation taking into account occupancy and room size

- Environmental conditions

The use of sorbents (gas absorbent materials) such as activated charcoal can be used to remove relatively high molecular weight VOCs such as toluene, benzene, xylene and methyl chloroform.

For lower molecular weight (MW) materials such as formaldehyde (HCHO), ethylene, and acetaldehyde then potassium permanganate, (KMnO4) activated alumina or specially impregnated charcoal are better choices than regular activated charcoal.

Other special air cleaners may also be used – consult ScanTech for further information.