Reference list on the plastics, pesticides and other solvent vapors which contribute to poor air quality, allergies, illness, airborne toxicity and carcinogenic risk.

NATURAL AND SYNTHETIC CHEMICALS

VOCs – can be classified by boiling points (VVOC, SVOC, VOC and POM) or by chemical structure such as aliphatic / aromatic hydrocarbons or functional R group composition such as oxygenated / halogenated hydrocarbons. Low volatility, high potency organic compounds and those with high polarity can be expected to preferentially take on the form of solid particles rather than remain in a vapor phase. Settled house dust or respirable suspended particles (such as those in the PM2.5 and PM10 size regimes) can also serve as reservoirs for both vapor phase SVOCs and POMs by adsorption. Exposure can be through inhalation, digestion or direct skin contact.

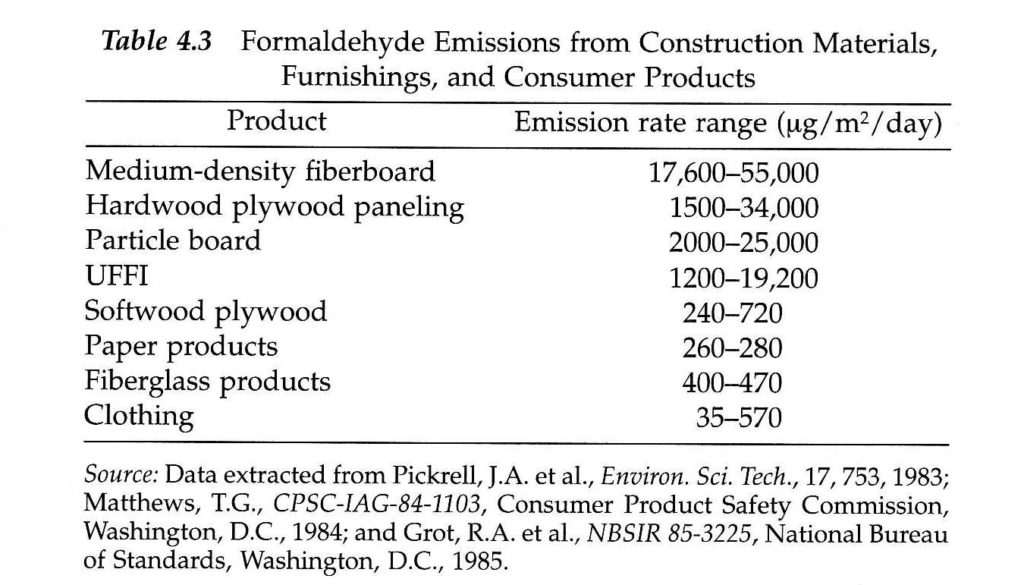

May come from a variety of sources including building materials, pesticides, air fresheners / aerosols, carpeting and linens. (including drapes)

Ozone (O3) ppm

Sulfur Dioxide (SO2) ppm

Nitrogen Dioxide (NO2) 5-35 ppb

Nitric Oxide (NO)

Carbon Monoxide (CO) 0 – 30+ ppm

Carbon Dioxide (CO2) 400 – 1000 + ppm (acts as a respiratory stimulant / increases breathing rate)

Polychlorinated Biphenyls (PCBs) found in electrical equipment

Aldehydes – Because of their solubility in aqueous media and high chemical activity due to the carbonyl functional group, aldehydes tend to be strong mucous membrane irritants affecting both the eyes and upper respiratory tract. This irritation tends to reflexively reduce respiratory rates which will also decrease oxygen intake. Significant examples include acrolein, (major eye / throat irritant in smoke and smog) glutaraldehyde (a biocidal used in medical, dental sterilization as well as duct cleaning and carbon-less copy paper) and acetalaldehyde which is a relatively weak irritant, though it is a proven animal carcinogen and found predominantly in combustion by-products such as cigarette smoke and automobile exhaust gas.

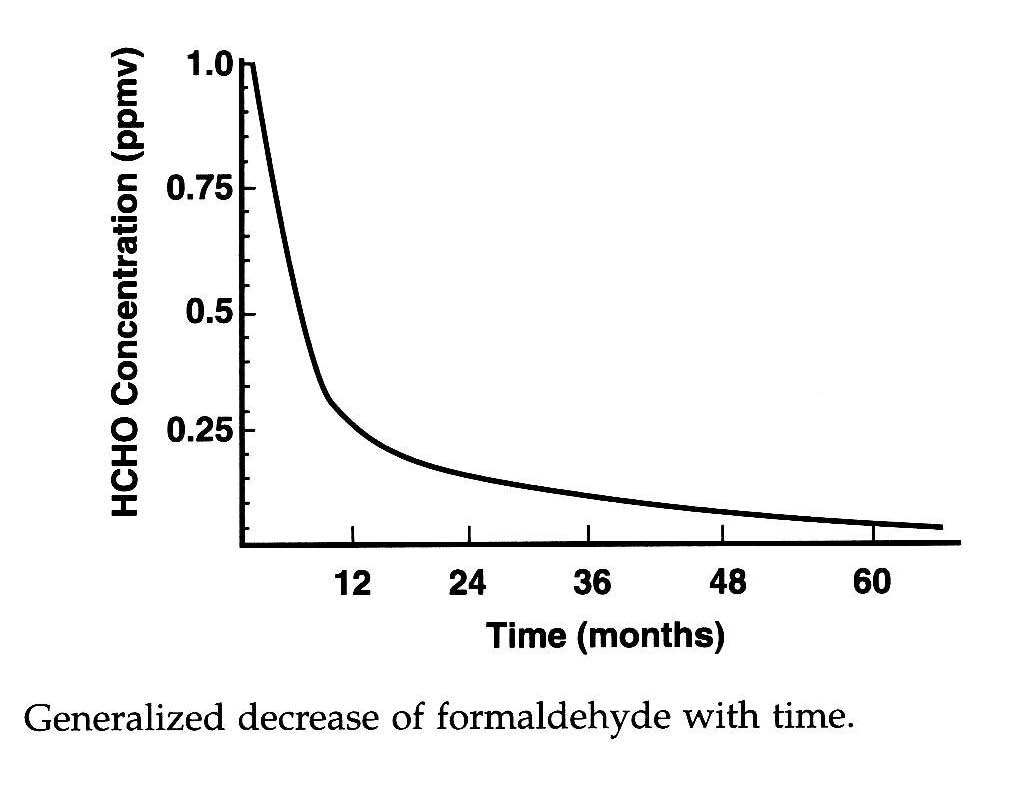

Formaldehyde (HCHO) 0 – 0.5 ppm

Fungicide – Pentachlorophenol, (PCP – used to prevent wood decay)

Pesticides: Organochlorines (chlordane, heptachlor – termiticides, p-dichlorobenzene for moth control)

Pesticides: Organophosphates such as dichlorvos, chlorpyrifos, diazinon, malathion can cause acute neurotoxicity but dichlorvos (used in bug bombs, dog and cat flea collars) has been phased out since 1988 due to potential for animal carcinogenicity except for chlorpyrifos (used for termites, cockroaches and fleas) and diazinon which was phased out in 2000 because of potential exposures to children.

Herbicide 2,4-D risk factor for non-Hodgkin’s lymphoma

Biocides – hypochlorites, glutaraldehyde, alcohols, o-phenylphenol, quaternary ammonium compounds, mercury (Hg) in latex based paint until 1990.

Plasticizers (phthalic acid esters) used to make vinyl more flexible and commonly found in floor coverings. Tends to leech out over time. Some evidence that it contributes to asthma.

Radon (Rn-222) picoCuries / liter

PARTICULATE MATTER

Allergens (dust, pollen, dust mites, pet dander)

Bacterial Endotoxins

Fungal Glucans and Mycotoxins from Mold

Total Suspended Particulate (TSP) Matter or Suspended Particulate Matter (SPM) and Respirable Suspended Particles (RSP) measured in particles / cubic foot or micrograms / cubic meter. The size regimes classified by the EPA are Fine particles PM2.5 which are 2.5 microns in diameter or less and Coarse particles PM 10 which are generally 2.5 – 10 microns in diameter.

Asbestos

Heavy Metals – Lead and Mercury in latex paint

HEALTH ISSUES

Respiratory / Mucous Membrane Irritation

Asthma

Hypersensitivity Pneumonitis

Humidifier Fever

Legionnaire’s Disease

Pneumonia

Bronchitis

SOURCES

Candles & Incense (particularly if burned during pregnancy) can contribute to risks of childhood leukemia. Incense may produce benzo-alpha-pyrene, polycyclic aromatic hydrocarbons (PAHs), and sinapaldehyde. (nasal carcinogen)

Propane fueled forklifts and burnishers (Carbon Monoxide)